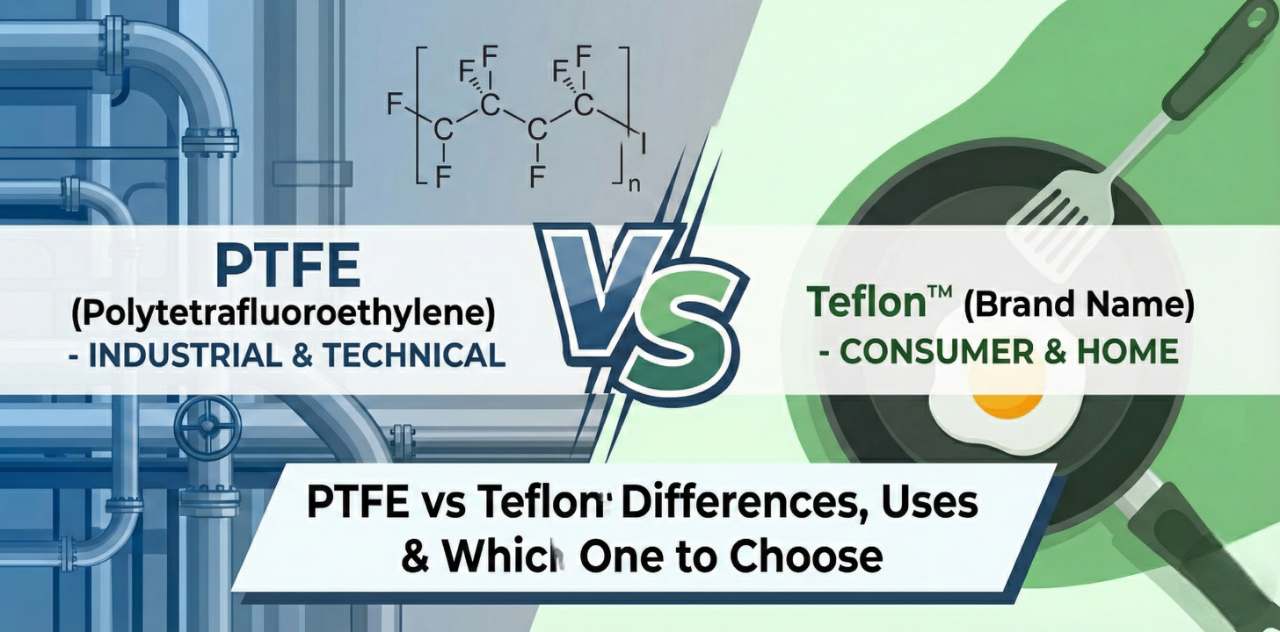

PTFE and Teflon are the same material chemically.

PTFE (Polytetrafluoroethylene) is the generic polymer, while Teflon® is a trademarked brand name used for PTFE-based products.

All Teflon is PTFE, but not all PTFE can be called Teflon.

PTFE (Polytetrafluoroethylene) is a synthetic fluoropolymer known for:

Extremely low coefficient of friction

Outstanding chemical resistance

High temperature stability (up to ~260°C)

Non-reactive, non-stick surface

Excellent electrical insulation

PTFE is widely used in:

Food and pharmaceutical equipment

PTFE is the globally accepted technical term used in datasheets, standards, and procurement documents.

Teflon® is a registered trademark, originally developed by DuPont and now owned by Chemours.

Only licensed manufacturers can legally use the name Teflon®.

Important clarification:

Teflon is not a different material

It is PTFE sold under a brand name

Using “Teflon” in technical specs without licensing is usually incorrect.

| Feature | PTFE | Teflon® |

|---|---|---|

| Type | Generic material | Brand name |

| Chemical structure | Polytetrafluoroethylene | Polytetrafluoroethylene |

| Performance | Identical | Identical |

| Trademark restrictions | No | Yes |

| Use in specifications | Preferred | Limited |

| Cost | Generally lower | Often higher |

| SEO value | High | Medium |

Both PTFE and Teflon share the same molecular structure:

Strong carbon–fluorine bonds

High chemical inertness

Thermal stability

Non-stick behavior

If two products are made from the same PTFE grade, performance will be identical, regardless of branding.

Catheter liners

Guidewire sleeves

Medical tubing

Heat exchanger liners

PTFE is used because it is biocompatible, smooth, and low-friction, reducing tissue damage and improving device performance.

PTFE-lined pipes

Gaskets and seals

Valves and fittings

Chemical transfer hoses

PTFE protects equipment from corrosion, scaling, and chemical attack.

Wire and cable insulation

High-frequency components

Semiconductor manufacturing

Non-stick cookware

Bearings and slide plates

(These often use the Teflon® brand for marketing.)

Choose PTFE if you are:

Writing technical or engineering specifications

Manufacturing medical or industrial products

Sourcing from multiple suppliers

Optimizing for SEO and AI visibility

Looking for cost-effective, standards-compliant materials

PTFE is the correct term for B2B, OEM, and export markets.

Teflon® may be relevant if:

Branding is important (consumer products)

You are using licensed Teflon coatings

A customer explicitly requests the Teflon trademark

For most industrial use cases, Teflon branding is unnecessary.

Neither is better — they are the same material.

The real difference is:

PTFE → technical accuracy, flexibility, SEO strength

Teflon® → brand recognition, trademark value

For engineering, manufacturing, and medical applications, PTFE is the better choice.

PTFE and Teflon are often confused, but the distinction is simple:

PTFE is the material

Teflon is the name

Understanding this helps buyers, engineers, and marketers:

Avoid overpaying

Write accurate specifications

Rank better in search and AI answers

Make informed sourcing decisions