Chemical

PTFE Pipe for Chemical Industries

High-Performance PTFE Lined Pipe for Chemical Safety & Reliability

At Yash Dynamics, we specialize in manufacturing PTFE fine powder extruded tubes, designed to withstand the most demanding chemical environments. With unmatched resistance to corrosive fluids, extreme temperatures, and harsh operating conditions, our PTFE solutions are trusted by leading chemical processing industries.

Why PTFE lined pipe for Chemical Use?

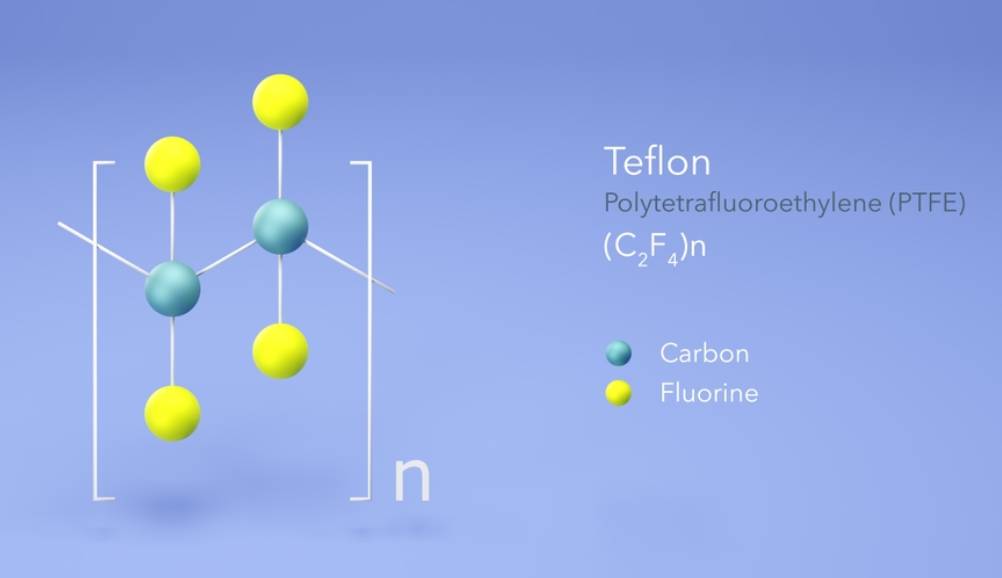

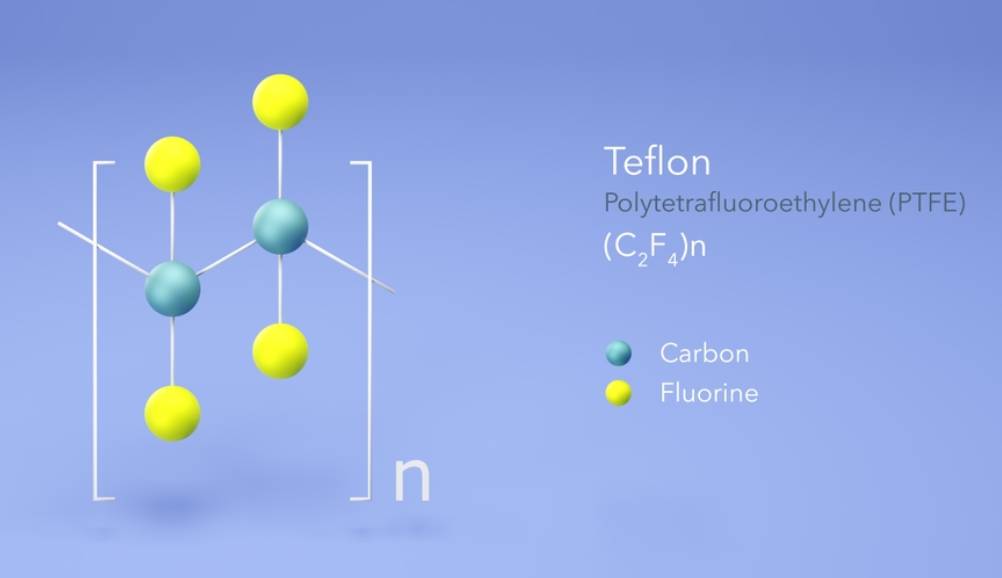

PTFE (Polytetrafluoroethylene), widely known as Teflon, is one of the most chemically inert materials available. This makes it the preferred choice for transporting aggressive chemicals, acids, and solvents.

Key Benefits for the Chemical Sector:

- Chemical Resistance – Safely handle corrosive fluids without degradation.

- Wide Temperature Range – Operational reliability from –270 °C to +260 °C.

- Non-stick & Low Friction Surface – Prevents chemical build-up inside tubes.

- Durability & Safety – Long service life, reducing downtime and replacement costs.

- Compliance Standards – FDA, EU, RoHS, PFOA-free, REACH, and USP Class VI certified.

Applications in Chemical Industries

Yash Dynamics PTFE lined pipes are widely used in:

- Chemical Transfer Lines – Safe conveyance of acids, alkalis, and solvents.

- Corrosive Fluid Handling Systems – Long-lasting performance in challenging environments.

- Protective Sleeving for Wires & Sensors – Prevents damage from chemical exposure.

- Tubing for Analytical Equipment – Ensures purity and contamination-free transfer.

Why Choose Yash Dynamics?

- Advanced PTFE Extrusion Technology – Engineered for Global Standards.

- Precision Manufacturing – Consistent concentricity and wall thickness.

- Global Standards Compliance – ASTM, DIN, IS quality benchmarks.

- Customer-Centric Service – Available in multiple sizes, colors, and custom lengths.

Contact Yash Dynamics

Looking for PTFE-based solutions for chemical processing?