PTFE (polytetrafluoroethylene) liners are high-performance fluoropolymer components that serve as protective or functional layers inside hoses, pipes, seals, bearings, and mechanical interfaces within automotive systems. With the automotive segment holding an 18% market share in 2024 and the global PTFE market projected to grow significantly, these liners have become indispensable in modern vehicle design.

The PTFE industry demonstrates robust growth, with market valuations reaching USD 3.63 billion in 2023 and projected to reach USD 5.25 billion by 2030, growing at a CAGR of 5.5%. This expansion is primarily driven by increasing demand from automotive applications, where PTFE liners reduce friction, resist chemical attack, and improve durability in demanding operating environments.

PTFE stands out due to its unique combination of physical and chemical properties that make it ideal for automotive applications:

Ultra-Low Friction Coefficient PTFE offers one of the lowest coefficients of friction at approximately 0.04 for both kinetic and static friction, compared to lubricated steel at 0.05 (kinetic) or 0.1 (static). This exceptional characteristic minimizes wear between moving parts and reduces energy loss in automotive systems.

Extreme Temperature Resistance PTFE operates reliably across a continuous use temperature range of -196°C to 260°C (-321°F to 500°F), with short-term working temperatures up to 300°C (572°F). This wide operational window ensures consistent performance from Arctic cold starts to high-temperature engine compartments.

Complete Chemical Inertness PTFE is chemically inert and does not react with fuels, oils, coolants, or brake fluids commonly found in vehicles. This resistance to chemical attack ensures long-term reliability and prevents degradation even with modern biofuel blends and synthetic fluids.

Superior Physical Characteristics

The automotive industry’s adoption of PTFE continues to accelerate. By 2024, over 12,000 tons of PTFE were used in electric vehicle battery insulations and e-mobility wiring systems, representing a 14.3% growth from 2022. This surge reflects the material’s critical role in next-generation automotive technologies.

Additionally, automotive applications consumed 22% of the global PTFE market in 2023, positioning it as one of the largest end-use segments. As vehicles become more complex, performance-driven, and electrified, the demand for materials that can withstand harsh conditions continues to rise, making PTFE liners increasingly important.

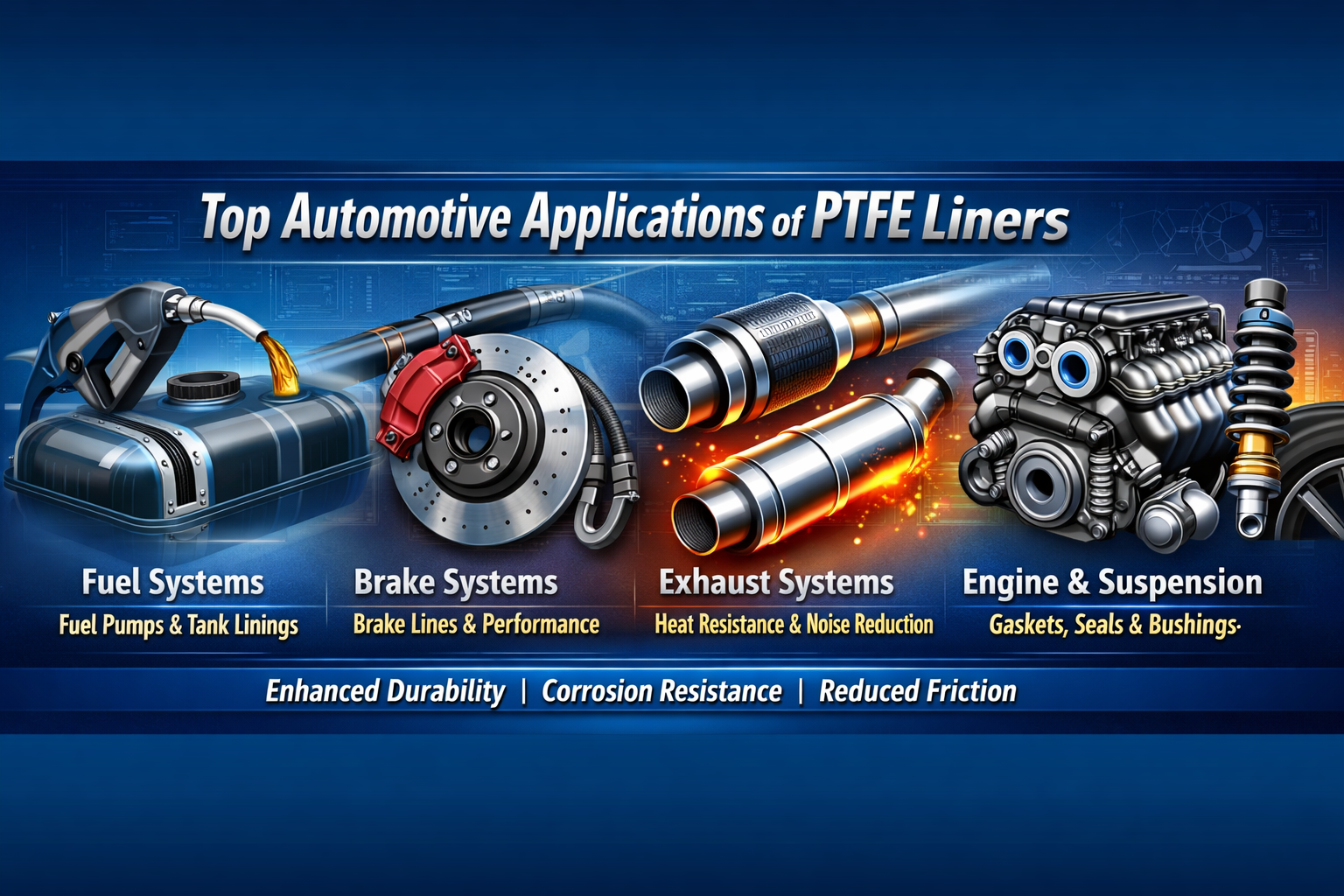

Fuel pumps are the heart of any vehicle’s fuel delivery system, requiring smooth, consistent fuel flow to maintain optimal engine performance. PTFE liners inside fuel pump components provide several critical benefits:

The non-reactive nature of PTFE ensures that fuel chemistry remains unchanged, which is essential for efficient combustion and emissions control.

Modern fuel tanks face numerous challenges including fluctuating temperatures, moisture exposure, and aggressive chemical compounds from blended fuels. PTFE liners provide:

This is particularly important as modern vehicles increasingly use alcohol-blended fuels, which can be significantly more corrosive than traditional formulations.

The use of PTFE liners in fuel systems delivers measurable improvements:

Brake systems represent one of the most safety-critical applications of PTFE in automotive engineering. Brake lines must withstand extreme conditions without compromising performance:

High-Pressure Integrity

Fluid Compatibility PTFE’s chemical inertness and temperature resistance ranging from -200 to 260°C make it ideal for hydraulic brake fluid applications, ensuring compatibility with DOT 3, DOT 4, DOT 5.1, and silicone-based fluids.

PTFE liner enable several critical performance improvements:

Faster Response Times By reducing internal friction, PTFE liners allow brake fluid to flow smoothly and predictably, resulting in:

Environmental Resistance Brake systems face constant exposure to:

PTFE’s corrosion and abrasion resistance ensures brake components last longer and perform reliably in all driving conditions.

The automotive industry recognizes PTFE brake lines as a premium upgrade:

While exhaust systems operate at extreme temperatures and face corrosive gases, PTFE liner find specialized applications in:

Flexible Joints

Sensor Housings

Gaskets and Seals

PTFE maintains stability at continuous temperatures up to 260°C (500°F), making it suitable for many exhaust system applications. While exhaust gases can exceed this temperature near manifolds, PTFE finds effective use in:

In certain exhaust applications, PTFE liners provide acoustic benefits:

Engine gaskets and seals must prevent fluid leaks while accommodating constant movement and dramatic temperature changes. PTFE liners excel in these applications due to:

Sealing Efficiency

Chemical Resistance

Friction represents a significant source of energy loss and component wear in engines. PTFE liners reduce surface friction between moving parts, delivering multiple benefits:

Performance Improvements

Fuel Efficiency Gains The coefficient of friction reduction translates directly to fuel economy improvements. Studies show PTFE-enhanced engine components can contribute to 1-3% better fuel efficiency in optimized applications.

By protecting engine components from wear and chemical damage, PTFE liners significantly extend engine life:

This reliability is especially valuable in modern engines that operate under tighter tolerances, higher pressures (up to 2,000+ bar in diesel injection systems), and more demanding thermal conditions.

Suspension systems rely on bushings and bearings to absorb shocks, maintain alignment, and provide stability. PTFE-lined components offer distinct advantages:

Maintenance-Free Operation PTFE has exceptionally low friction with coefficients between 0.05 to 0.1, making it ideal for bearings at low speeds. This self-lubricating characteristic means:

Load-Bearing Capacity PTFE-composite materials can handle demanding suspension loads while maintaining low friction. PTFE filled with fiberglass, graphite, or other materials can be used at PV values up to 10,000 or more, making them suitable for heavy-duty applications.

The integration of PTFE liners in suspension components delivers measurable improvements:

Enhanced Response

Reduced Friction and Resistance Lower resistance in suspension pivot points allows the system to respond more freely to road inputs, resulting in:

Minimizing play and wear in suspension joints through PTFE liners contributes significantly to improved vehicle dynamics:

Steering Precision

Handling Characteristics

Long-Term Consistency Unlike traditional rubber bushings that degrade and soften over time, PTFE-lined components maintain their characteristics longer, preserving vehicle handling throughout the ownership lifecycle.

The electric vehicle revolution has created new opportunities for PTFE applications. Over 2,500 tons of PTFE flame-retardant composites were used in EV battery management systems, reducing fire propagation risk by 47% while maintaining insulation resistance above 10⁶ ohms.

Battery Pack Applications

Over 12,000 tons of PTFE were used in battery insulations and e-mobility wiring systems by 2024, highlighting the material’s critical role in electric powertrains:

Electric vehicles require sophisticated thermal management, where PTFE excels:

The PTFE automotive market shows strong momentum across multiple forecasts:

The global polytetrafluoroethylene market size was valued at USD 3.63 billion in 2023 and is projected to reach USD 5.25 billion by 2030, growing at a CAGR of 5.5%

The global polytetrafluoroethylene market was estimated at USD 3.85 billion in 2024 and is predicted to increase to approximately USD 6.61 billion by 2034, expanding at a CAGR of 5.54%

The PTFE Market is expected to reach 224.82 kilotons in 2025 and grow at a CAGR of 4.67% to reach 282.45 kilotons by 2030

Asia-Pacific Dominance Asia Pacific dominated the global market with the largest market share of 45% in 2024, driven by:

North American Growth North America is anticipated to witness the fastest growth during the forecasted years, fueled by:

Autonomous Vehicle Systems

Hydrogen Fuel Cell Vehicles Solvay developed new PTFE membrane technology for hydrogen fuel cells, rolling out over 600 tons in 2023, demonstrating PTFE’s expanding role in alternative powertrains:

Advanced Manufacturing More than 7,200 tons of PTFE materials were used in 3D printer filament production globally in 2023, with industry uptake increasing by 17.8%. This enables:

The PTFE industry faces evolving environmental regulations. The European Chemicals Agency’s 2025 draft restriction on PFAS threatens broad classes of fluoropolymers unless exemptions for essential uses are retained. Industry responses include:

Major processors respond by launching PFAS-compliant or PFAS-free product lines; Avient introduced a PTFE-free LubriOne range for precision gears and bushings in early 2024. However, for critical automotive applications where performance and safety are paramount, PTFE remains irreplaceable due to its unique combination of properties.

Friction Characteristics

Temperature Performance

Chemical Resistance

Mechanical Properties

Across fuel systems, brake assemblies, exhaust components, engines, and suspension systems, PTFE liners play a crucial role in enhancing performance and durability. Their ultra-low friction (coefficient of 0.04), complete chemical resistance, and exceptional thermal stability (-196°C to 260°C) make them one of the most versatile materials in automotive design.

The quantifiable benefits include:

As vehicles continue to evolve with electric powertrains, autonomous systems, and higher efficiency standards, the use of PTFE liners is expected to grow substantially. The market’s projected expansion from USD 3.63 billion in 2023 to USD 5.25 billion by 2030 underscores this trajectory.

Key Growth Drivers

Innovation Opportunities AI integration in PTFE manufacturing provides enhanced quality control, optimized processes, and defect reduction, while material science advances continue to develop new PTFE formulations for specific automotive applications.

PTFE liners have become an essential component in modern automotive engineering. Their ability to improve reliability, enhance safety, and increase efficiency ensures they will remain a key material choice for manufacturers aiming to meet the demands of today’s and tomorrow’s vehicles.

From internal combustion engines to electric powertrains, from conventional hydraulic brakes to advanced regenerative systems, PTFE’s unique properties continue to solve engineering challenges that other materials simply cannot address. As the automotive industry undergoes its most significant transformation in over a century, PTFE liners will undoubtedly play an increasingly vital role in shaping the vehicles of the future.